Exploring Self-Certification and Safety-Certified Components

As robots continue to proliferate across industries, a critical dialogue around functional safety – ensuring safe operation amidst unexpected events – becomes paramount. Engineers and robotics firms grapple with a critical decision: Should they opt for self-certification of all components or use pre-certified safety components?

We will introduce the very basics of functional safety in robotics and the pros and cons of self-certification versus the utilization of safety-certified components, underpinning the advantages, challenges, and key considerations associated with each. Our objective isn’t to prescribe one route over another, but rather, to empower engineers with knowledge, enabling informed decision-making based on specific project needs, resources, and industry standards.

We will also touch upon the role of how MorpheusTEK can support navigating this complex landscape, providing robust sensor solutions and valuable consultation services.

Understanding Functional Safety in Robotics:

Functional safety is a crucial aspect of any system where failure could result in harm to people, damage to the environment, or significant economic loss. This is particularly pertinent in the field of robotics. In this context, functional safety refers to the system’s ability to operate correctly and safely in response to its inputs, even in the event of unexpected or fault conditions.

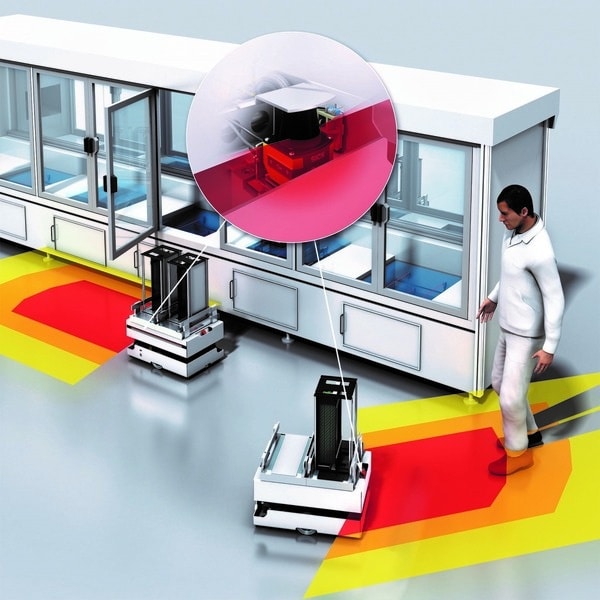

Robots frequently operate alongside humans or valuable assets, whether in industrial environments, public spaces, or private residences. The need for these robots to be functionally safe is paramount, preventing accidents and ensuring reliable operation. Functional safety in robotics spans several layers, encompassing accurate environmental perception, sound decision-making based on this data, precise execution of commands, and secure handling of unexpected events or errors.

To achieve functional safety in robotics, safe design and construction are just the starting point. It also necessitates extensive testing, regular maintenance, and appropriate usage. Moreover, documentation of safety measures and evidence of compliance with safety standards is often required, particularly in commercial applications.

Various standards guide the practice of functional safety in mobile robotics, examples are:

ISO 26262 – Road Vehicles Functional Safety: While primarily intended for automotive applications, this standard has been widely adopted in the mobile robotics field due to its comprehensive guidelines for managing the lifecycle of safety-related electrical and electronic systems. It includes provisions for development, production, operation, and decommissioning, incorporating elements such as risk assessment, safety requirements specification, and verification and validation processes.

ANSI/RIA R15.08-1-2020: This standard is specifically designed for industrial mobile robots, providing safety guidelines for their design, manufacture, and integration. It includes requirements for the robot itself, the end-effectors, and any peripheral devices, as well as for the robot’s operating environment.

ISO 13849 – Safety of Machinery: This standard gives safety requirements and guidance on the principles for the design and integration of safety-related parts of control systems, including software design. Even though it is primarily focused on machinery, many of its principles can be applied to mobile robots, especially those used in industrial environments.

The standards listed above are not comprehensive, and the landscape of safety guidelines continues to evolve. Functional safety remains a paramount concern in robotics, warranting meticulous attention and strict adherence to relevant standards throughout a robot’s lifecycle.

Your choice between self-certifying components or using safety-certified ones doesn’t circumvent the essentiality of understanding and implementing functional safety principles. These principles are fundamental to building a dependable, effective, and safe robotic system.

In navigating these intricate standards and making the right choices for your robotic project, MorpheusTEK stands ready to assist. We’re here to help you select and comply with the most appropriate standards for your specific needs, providing support every step of the way.

Method 1: Self-Certification

Self-certification is an approach where a company assumes full responsibility for ensuring that their product or system complies with all relevant safety standards. In the context of robotics, this involves validating every component of the system, from sensors and actuators to control software and communication protocols.

Process of Self-Certification:

The self-certification process generally begins with a thorough risk assessment to identify potential safety hazards that the robot might encounter during operation. Each component is then designed and tested individually to ensure it performs its function correctly and safely, even under fault conditions.

Once each component has been tested, they are integrated into a complete system. The whole robot is then subjected to extensive system-level testing to verify that all components work together as intended, and that the overall system behaves safely under various operating conditions and in different scenarios. This can involve a range of tests, from functional tests and stress tests to fault injection tests and field tests.

Throughout this process, comprehensive documentation is maintained to provide evidence of compliance with safety standards and to support future maintenance and troubleshooting efforts. This documentation can include design documents, test plans, test results, risk assessments, and mitigation measures.

Advantages of Self-Certification

One of the main advantages of self-certification is the potential for greater flexibility. Companies can design and adapt their robots to meet specific needs or unique operating conditions, rather than being limited to off-the-shelf components that have been certified by a third party. This can also enable faster innovation, as new technologies and techniques can be incorporated as soon as they are developed, without waiting for them to be certified by an external entity.

Challenges and Drawbacks

However, self-certification also comes with its own set of challenges. The process can be time-consuming and resource-intensive, requiring a high level of expertise in safety engineering and a thorough understanding of the relevant safety standards. In addition, there is the risk that some aspect of the system might not meet the safety standards, leading to potential safety issues and liability concerns.

Moreover, the responsibility for maintaining the safety of the system throughout its lifecycle rests solely on the company. This includes not only initial certification, but also regular safety audits, updates to the safety case as the system or the operating conditions change, and decommissioning at the end of the system’s life.

In conclusion, while self-certification offers flexibility and the potential for faster innovation, it also requires significant resources and expertise, and comes with the burden of ongoing responsibility for system safety. Companies considering this approach need to carefully weigh these factors against their specific needs and capabilities.

Method 2: Using Safety-Certified Components

Safety-certified components refer to parts that have been evaluated and certified by an external entity to meet certain safety standards. This certification implies that these components, when used correctly, should perform their intended functions reliably, even under fault conditions. In the context of mobile robotics, these could range from sensors and actuators to control systems and software.

Contribution to Overall Functional Safety

The use of safety-certified components can substantially contribute to the overall functional safety of a robot. Since each component is already certified to meet certain safety requirements, integrating them should ideally result in a system that, as a whole, is functionally safe. This can simplify the process of ensuring functional safety, as the focus can then shift to system-level considerations rather than validating each component individually.

However, it’s essential to remember that just because a system is composed of safety-certified components doesn’t automatically guarantee that the system as a whole is functionally safe. The integration of these components, their interactions, and the overall system design and operation still need to be considered and tested.

Advantages of Using Safety-Certified Components

One of the main advantages of using safety-certified components is the assurance of compliance with safety standards for those components. This can reduce the time and effort required for system certification, as the need for individual component testing is lessened.

Additionally, using safety-certified components can help mitigate liability concerns, as the responsibility for the safety of the components lies with the certifying entity. This can also facilitate communication with regulatory bodies or clients, as the certifications provide a universally recognized assurance of safety.

Challenges and Limitations

Despite these advantages, there are potential challenges and limitations to consider. One of the main limitations is the potential lack of flexibility. Safety-certified components are typically off-the-shelf products, which may limit customization options and may not perfectly align with the specific needs of the robot or its operating conditions.

Another challenge lies in ensuring compatibility and safe interaction between different safety-certified components. Just because individual components are safe doesn’t necessarily mean they will interact safely, especially in complex systems like mobile robots.

Lastly, the cost of safety-certified components can be higher than non-certified equivalents, due to the additional testing and certification processes they undergo. This can be a significant factor, particularly for small companies or startups with limited budgets.

In summary, using safety-certified components can streamline the safety certification process and provide a certain level of assurance regarding component safety. However, considerations about flexibility, system-level safety, and cost should also factor into the decision-making process.

Comparative Analysis: Self-Certification vs. Safety-Certified Components

When choosing between self-certification and using safety-certified components in the development of mobile robots, several factors come into play. These factors include cost, time, reliability, compliance with safety standards, flexibility, and the specific requirements of the project.

Cost: While the direct costs of components for self-certification can be lower, the overall expenses associated with this approach may escalate. The need for specialized skills, the labor intensity of the certification process, and the requirement for testing equipment could increase costs. In contrast, safety-certified components might come with a higher upfront price tag, but they can significantly curtail certification-related expenses.

The final balance between these costs will hinge upon specific factors, such as the nature and quantity of the components, the complexity of the systems involved, and the organization’s available internal resources. When factoring in production volumes, the overall cost of a product could potentially be lower with self-certification, but this isn’t a given. It is crucial to perform a comprehensive cost analysis specific to the project at hand to make an informed decision.

Time: Self-certification can be time-consuming, particularly for complex systems or novel technologies. It requires extensive testing and documentation, which can extend the product development cycle. On the other hand, using safety-certified components can shorten the certification process, but it may also impose constraints on the choice of components, which could potentially extend the design phase.

Reliability: Both methods aim to ensure reliable operation of the robot. While using safety-certified components provides assurances based on third-party evaluations, self-certification allows a deeper internal understanding of the system and its failure modes. The choice might depend on whether the company values external validation or internal knowledge more highly.

Compliance with Safety Standards: Both methods require compliance with relevant safety standards. With self-certification, the company needs to demonstrate this compliance, which can be a complex process. Using safety-certified components comes with built-in compliance for those components, simplifying this aspect.

Flexibility: Self-certification offers more flexibility in terms of system design and the ability to incorporate novel technologies. This is particularly beneficial for unique or innovative applications. Using safety-certified components may limit design choices, but offers the advantage of pre-validated, reliable components.

Preferred Scenarios: Self-certification might be preferred when the company has a high level of safety engineering expertise, requires novel technologies or bespoke designs, and when the resources for extensive testing and documentation are available. In contrast, using safety-certified components might be more suitable for standard applications, when the company lacks the resources or expertise for self-certification, or when third-party validation is particularly important for the market.

The choice between self-certification and using safety-certified components depends on a balance of several factors, which will be influenced by the specific project requirements, the company’s resources and expertise, and the intended application of the mobile robot. Both methods have their advantages and potential drawbacks, so the best choice will depend on the specific circumstances of each case.

Conclusion

The journey towards ensuring functional safety in robotics can take many paths, and it’s critical to weigh the pros and cons of self-certification versus using safety-certified components. This decision is multifaceted, involving factors such as cost, time, reliability, compliance with safety standards, and flexibility.

Self-certification, while potentially more labor-intensive and time-consuming, can provide a deeper understanding of your system’s functionality, particularly when leveraging advanced sensors like OLEI’s non-safety LiDAR supplied by MorpheusTEK. This approach affords the flexibility to design and certify unique, tailored solutions.

On the other hand, utilizing safety-certified components, such as OLEI’s safety-certified 2D LiDAR, also available from MorpheusTEK, can streamline the safety certification process. This method can offer universally recognized assurances of safety, freeing up resources for system-level safety considerations.

MorpheusTEK, with its profound knowledge in robotics sensors and engineering consulting, stands ready to assist in either scenario. Whether you need guidance in selecting appropriate safety-certified components, understanding the safety certification process, or navigating the intricacies of self-certification, MorpheusTEK’s unique technical expertise and problem-solving capabilities will be invaluable.

Remember, regardless of the path you choose, the ultimate goal remains the same: to build robotic systems that are safe, reliable, and effective in a wide array of environments and applications. This journey, brimming with innovative technology and rigorous safety practices, is one we at MorpheusTEK are deeply committed to, working alongside our clients and partners.

In conclusion, determining how best to achieve functional safety in mobile robotics is not merely an important conversation—it’s a fundamental one. Whether your inclination is towards self-certification, using safety-certified components, or a combination of both, we encourage continued discussion and exploration in this field. You have a ready partner in MorpheusTEK, standing by to support you in creating safer, more intelligent, and more capable robots.